The invention of keyless drill chucks was a game-changer in making the best cordless drills easier to use. If I asked if you knew how to use a keyless drill chuck, you might be tempted to throw something at me for insulting your intelligence. But let’s hold off on that for right now, because we come across quite a few folks who actually use it incorrectly.

Chuck History 101

If you’re not up to speed on your drill design history, many of us started with a keyed chuck. It’s that mysterious-looking thing that clips to the cord on your Dad’s old drill. When you insert it into a hole on the chuck, it creates a gear system that allows you to tighten or loosen it. Lose the key and you’re out of luck until you locate another one.

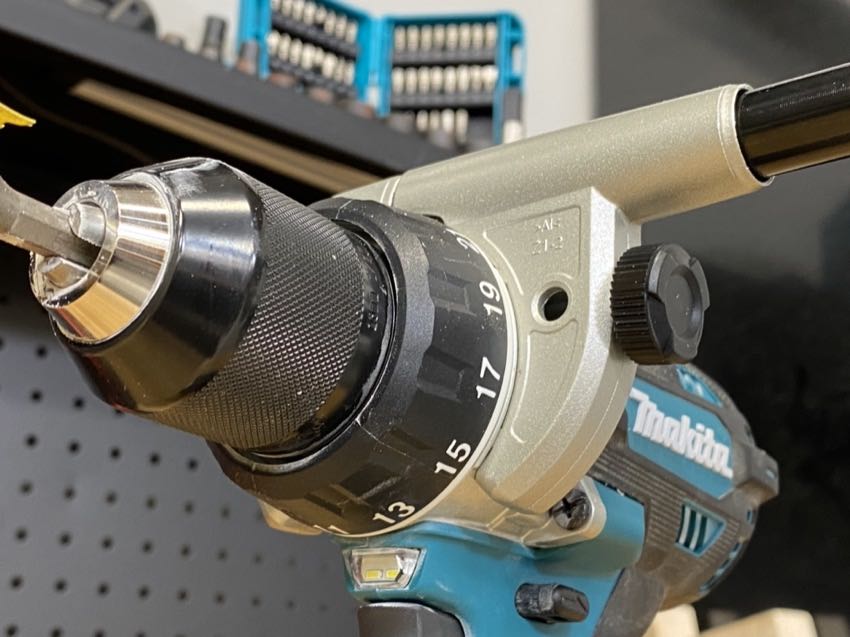

Keyless drill chucks came along and I think we all breathed a sigh of relief when we used them for the first time. Instead of using a key, all you have to do is twist the chuck until you feel it tighten down on your bit and start drilling. Most have a ratcheting action that you can feel as it tightens.

How to Use a Keyless Drill Chuck

Have you ever started drilling a hole or set a screw only for the bit to slip right out?

Manufacturers designed the ratcheting mechanism on a keyless chuck to prevent this. We see a lot of folks in the field (and are sometimes guilty of it ourselves), just hold the chuck and press the trigger until the drill holds the bit in place. Some people have more success than others, but it doesn’t always engage the locking mechanism properly.

The Following Works on Ratcheting Chucks

You need to make sure you turn the chuck by hand until you feel it ratchet down.

So here’s how you use a keyless drill chuck more effectively:

- Hold your favorite drill or driver bit and turn the chuck until the teeth engage the bit (you can use the trigger to help if you prefer).

- Hand crank the chuck tighter until you feel it ratchet down. That’s it – simple!

Once you’re engaging the ratcheting mechanism, you should experience fewer instances of your bit slipping out. It might also reduce the amount of ribbing you get from your friends.

What About Non-Ratcheting Drill Chucks?

Non-ratcheting chucks certainly exist. These days, we find them mostly on older or entry-level tools. Cordless drills from no-name companies or products that attempt to truly cut as many corners as possible can use non-ratcheting chucks to trim costs. You also find them on older products made before the inception of the ratcheting chuck.

The problem with non-ratcheting chucks is you never truly get a good bite on your bit. Even if the system does a good job holding the bit initially, it can loosen up as soon as you stop the drill.

What happens is that the action of the brake rapidly stopping the chuck causes it to loosen. Many a Pro has lost an expensive spade bit or hole saw in an attic or down a wall cavity when a non-ratcheting chuck decides to release its grip and drop a bit.

Did that help you drop fewer bits? We hope so! If you have additional questions or more feedback, be sure to let us know in the comments below.

I cant help but to clearify that a keyless ratcheting chuck is not the same as a chuck with a ”clicking” when tightening the chuck. The audible click is only there to help you know that you are in the last ”tightening” phase of the tightening rotation of the chuck. There are non-clicking keyless ratcheting chucks also that does a great job retaining the bit/drill.

Peace!

You kind of dropped off in the middle in your “wrapping it up” section on the loosening keyless chucks. What’s the solution with non-ratcheting chucks? If none available, just say so. I have a ryobi cordless lithium to which I’ve retrofitted a machinists precision keyless chuck. This is way beyond the typical keyless chucks found on commercial electric drills. The advantage is the jaws close to zero, allowing the chucking of very small drill bits. You’ll notice many cheaper chucks have a big hole in the middle of the closed jaws. Anyway, yes, the heavy industrial keyless chucks have so… Read more »

Hi there ! How’s everyone doing today?

Great article Mr.Koehler but you missed one thing…

The key (🤣no pun intended)as I just recently discovered , is turning the Chuck BACK one notch after doing those other two things you stated.

Amazing! I didn’t know this either …

I just had a problem with a Brad bit slipping off my DCD996 the other day and getting stuck in the piece of wood.

I looked around the net and found this:

https://www.youtube.com/watch?v=xIYZIWPRBos

🙏🏼🤠😎❤️😘🌕🌹🐚✨❄️

Actually been using the 1/4” snap lock on Metabo for fifteen years, the six sided drill bit engages better than round ever could, how ever good the chuck was.

Use it as a half inch driver for nut running on Prius Battery rebuilds too, will cut up to inch diameter in timber, all with snap in, throw out your old plain round shafted drill sets right now !

“Get a good bit on your bit”