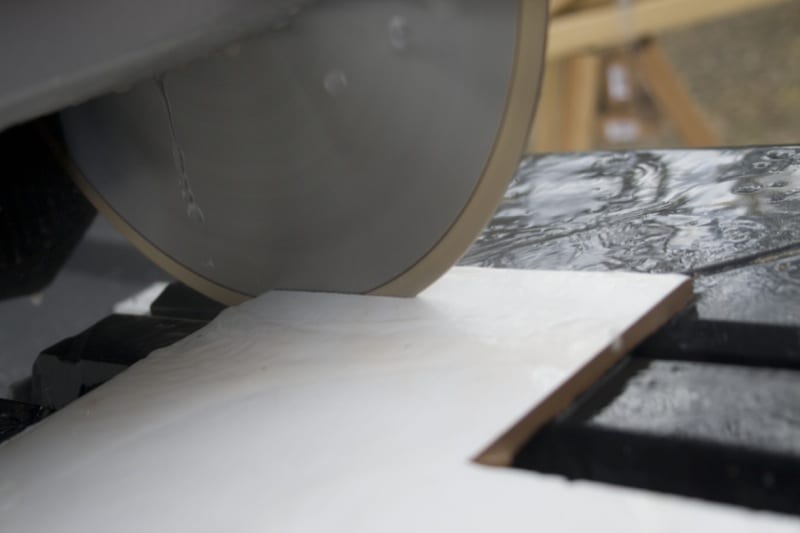

As a longtime player in every other aspect of professional building and installation tools, it should come as no big surprise that Bosch introduced a wet saw for cutting tile and thin stone. This Bosch TC10 tile saw review looks at this 10-inch blade saw and sees if it can compete with the best full-size professional tile saws on the market.

Instead of building a new saw from the ground up, Bosch chose to adapt a well-liked saw design for the TC10 that had been introduced several years ago and is still sold in the US and Europe under different brand names. Manufactured in concert with a partner tool company in a co-owned factory, Bosch has had a hand in the making of this saw since its inception.

To further the design of the TC 10 beyond previous versions and make it truly their own, Bosch made a few modifications intended to serve their pro users better. They ditched the laser line guide and LED work light mounted under the motor housing and tweaked the plunge cut handle attached above. Bosch also added side drip trays, in addition to raising the end of the existing rear tray to catch water spray more effectively. They also added a slightly larger rolling table extension but removed the fence on the extension. We appreciated most of Bosch’s efforts here but took exception with this last little detail.

Out of the Box

With 27 inches between the blade in its lowest position and table’s fence, the Bosch TC10 tile saw can easily handle 24-inch tiles on straight cuts and 18-inch tiles diagonally. Like other saws with a 24-inch tile capacity, this tool requires a lot of floor space, especially once all the drip trays have been attached. The overall length from front to back is just over five feet at full extension, and the overall width is almost three feet. Its large footprint could keep you from fitting it in a smaller-sized bathroom during a remodel.

I measured the accuracy of the saw components as set by the factory, and I was generally impressed with what I found. The inch scale on the fence of the rolling table was right on as were the 22 1/2-, 45-, and 90-degree bevel angle settings of the saw head. If the angles ever drift, there are adjustable stops for both 90 and 45 degrees. The fence stop device that clamps to the fence for making repetitive cuts had accurate inch marks, but the 45-degree setting on its protractor was a bit off.

The rolling table was very stable and moved smoothly via four grooved, horizontal ball-bearing wheels that glide on round stainless steel rails. The table travel was not precisely perpendicular to the blade but was only off about .020-inch over the length of a 24-inch tile—certainly close enough for cutting tiles set with a grout joint. If needed, the user manual contains detailed instructions for recalibrating the table to the blade.

The easily-removable extension to the rolling table fit in its slots readily; unfortunately, even though equipped with four adjustable set screws, it proved impossible to adjust. The extension hung parallel to, but just below, the level of the table—a situation that cannot be remedied if the set screws are already back as far as they can go (as mine were). This meant that the extension didn’t offer support unless a tile was tilted down to the right slightly.

When I tried to adjust the right side of the extension up (so at least its far edge would support a large tile) all of the tiny set screws refused to budge, and I ended up with four, stripped-out hex socket heads and a rounded-over hex wrench. The gap was only 1/16-inch, but it’s a bit frustrating to have no provision to fix it short of covering the entire extension with shim material or taking a file to the connections at the bottom.

Bosch TC10 Tile Saw Performance

On the job, the standout features and limitations of the Bosch TC10 tile saw became apparent pretty quickly. Tile saws—relatively simple machines—get tasked with only a few things. Cut tile in a straight line without chipping, supply sufficient water to the cut, and try to contain most of that water. The other reason features and limitations were readily apparent was because it was on the job with Joe Brown, a veteran tile contractor of 40 years. He also happens to be quite a knowledgeable tool buff.

Like most tile saws with universal motors, the TC10 saw doesn’t have an automatic motor brake. And unlike most tile saws, the power cord has an integrated GFCI module to protect the saw and user in wet locations. Both features can eventually go bad and become a maintenance hassle, but it was nice to have the extra measure of electrical protection.

The diamond blade provided with the saw revealed a discernible dish when held against a straightedge. When its initial cuts showed chipping, it was replaced with a preferred blade for the duration of the testing.

Rolling Table

A saw’s table really is the heart of a tile saw. Its operation determines the accuracy and ease of use of the saw more than any other single component. The action of the Bosch table is very smooth which makes for clean, accurate cutting. It allows a maximum cut of 13-3/16 inches to the left of the blade (the clearance between the blade and saw head support arm). When using the fence stop to set your cut, however, its width only allows a maximum setting of 7-1/4 inches to the left of the blade.

To the right side of the blade the maximum setting of the stop is a scant 3-1/2 inches. Since most large tiles have to be held to the right side of the table, we wished Bosch had included a fence on the table extension. Limiting the capacity of the fence stop like this makes repetitive cuts on large tiles more of a chore for the tile contractor and detracts from the experience of using this saw more than anything else we found.

Plunge Cutting

The plunging action of the saw head works very well. The spring tension is just right, and the saw head can be easily adjusted to the desired maximum depth of cut with the attached depth stop knob and jam nut. To secure the head back down for standard cutting, the rubberized surface of the depth adjustment locking knob provides a sure grip for snug tightening. We noted there was relatively low clearance under the motor housing. The position of the saw head mounting arm in line with the front of the blade allows less room for cutting out square and curved notches in large tiles than saws designed with the mounting arm set well behind the plane of the blade.

Water Management

The Bosch TC10 tile saw does an excellent job of controlling stray water (and the tile powder it carries) which keeps the job site drier and cleaner. In fact, my tile contractor commented that the Bosch saw has the best water containment and is the cleanest product he’s ever used.

Along with a heavy, rubber wraparound splash shield mounted to the bottom of the blade guard, the curved-up design of the rear tray is a key performance feature for blocking the spray of water directly behind the blade. In addition, the generous side trays catch drips from tiles overhanging up to 16-1/2 inches to the right of blade.

A sturdy little pump supplies adequate water for cool cutting, but its included hose isn’t long enough to dangle the pump down into a bucket of clean water if that’s how you prefer to work. The nozzles that provide water to the blade cannot be directed as close to the cut as with some other modern saws, but at least the angle that the water streams against either side of the blade from the back can be adjusted.

Since a bucket won’t fit under either the rolling or folding stands, the water pan must be slid out several inches to drain. The pan drains down to 1-1/2 quarts, and it is stiff enough to remove and pour out the remainder without trouble. Another nice feature is the soft plug that seals well even in cold temperatures. Luckily, its chain tether means it won’t easily be lost.

Stands and Portability

A standard X-shaped folding stand (GTA10) comes with the TC10-07 saw setup. It’s certainly sturdy enough, and the adjustable feet can position the stand at either 28-1/2 or 29-3/4 inches tall. Holes in the bottom let you bolt the saw to the stand if desired, but the bolts aren’t provided. We also tested the optional collapsible rolling stand (GTA10W) that is available for an additional $190.

This stand is a bit lower at 27-3/4 inches tall and the extra leaning down exacerbates the feeling of really stretching out for the saw’s long table travel. This rolling stand adds mobility while the saw is set up or while moving it onto the job. The stand carries most of the attached saw’s weight while rolling it over driveways and yards. The rubber-tired wheels aren’t very big, but they rolled across frozen ground and skied admirably through the snow during our winter testing. As you might guess, climbing stairs was not really their specialty.

Once in place on the job, you fold down the legs, tighten a locking knob, snap down the wheel brakes, and you are ready to go. Quick setup is a desirable trait in a saw. Tile contractors are all too aware that they’re not making any money until they are setting tile. The downside of this stand is that it adds considerable heft and therefore a degree of back-wrenching peril to the tasks of loading the saw into a truck and/or navigating stairs alone. The stand can be unscrewed from the saw without tools in a minute or two, but that’s time that could be spent working, so it almost never gets done.

Wrapping It Up

After putting this saw to work on a couple of upscale custom tile jobs cutting materials from soft travertine to hard porcelain, we can say that the Bosch TC10 is truly a great saw for professional use. It performed every type of cut well while keeping stray water in check better than most other saws. The only real disappointment with this saw was the lack of a fence on the extension table and, to a lesser degree, the inability to adjust the extension to match the exact height of the rolling table.

And if we got a chance to redesign the saw we would consider adding a second, closer position to bolt the saw head to for cutting 12-inch and smaller tiles. The reach of 30 inches or so felt like a stretch when cutting smaller tiles that don’t require long table travel.

Michael Springer is a tool tester and tool industry journalist based in Boulder County, Colo.

Thanks to Boulder, Colo. area tile contractor Joe Brown for his expert contribution to this tool test.

Joe Brown Tile, 303-651-3605

please don’t buy this saw. I bought it, and in a few years the wheel bearing went bad and the replacement part is discontinued. I’ve always been a Bosch fan but I’m completely disappointed with them. Wheels are usually the first thing to break,I don’t get why they don’t provide parts for that. Now I’m throwing away a $1000 saw.