iQ Power Tools is not new to the market of dust-free cutting tools. They started awhile back with machines designed to cut larger stone or block. More recently, however, they introduced the iQ Power Tools iQTS244 Dry Cut Tile Saw. This wall and floor tiling tool is unique in that it cuts ceramic, porcelain, marble, and stone tile—all without water. They do this through the use of both a unique 10-inch dry-cut tile saw blade and a completely integrated dust control system. If you cut tile, this is revolutionary. It allows you to cut tile inside or outside with no water and almost no dust discharge. In terms of cleanup alone you could easily save an hour per job.

iQ Power Tools Dry Cut Tile Saw Features

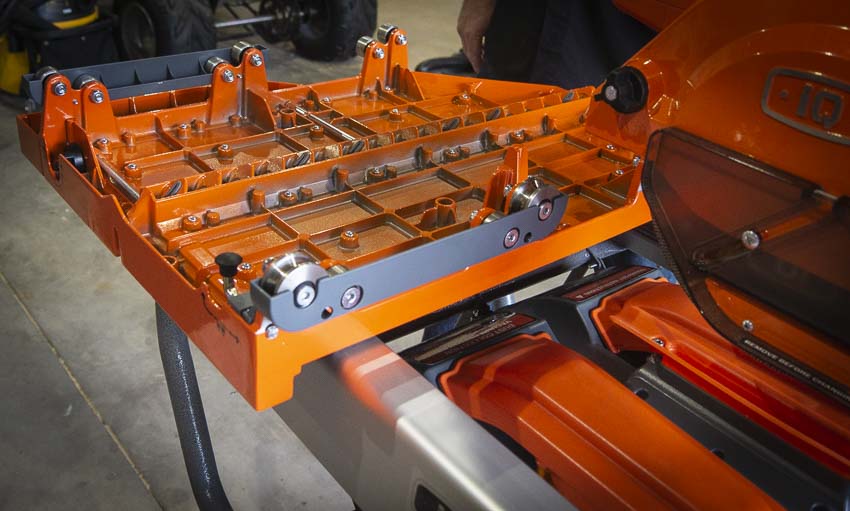

We not only had the iQ Power Tools Dry Cut Tile Saw here for review, we also got a chance to spend some one-on-one time with Paul Guth, vice president of research & development for iQ Power Tools. He gave us a quick once-over on the dry cut tile saw and also gave us some insights on some of the design goals. Of primary importance, the iQ Power Tools iQTS244 saw is 100% compliant with the new OSHA standard for respirable silica dust. To accomplish this, it uses a three-stage filtration system to capture up to 99.5% of the dust. You can actually see the three stages since the dust tray is divided accordingly into three sections:

- First Stage: Heavy Debris Filtration

- Second Stage: Cyclonic Filtration (Fine Particles)

- Third Stage: iQ Dura Bond Filter Cartridge (Super Fine Particles)

The reason iQ Power Tools achieves such great dust collection is that they have a guard that stays close to the table at all times. Additionally, miter cuts are done by tilting the tile—not the blade. That way, the blade stays positioned directly overtop the dust collection port at all times. You simply move the tile through the cutting and vacuuming path. In fact, the first time you start up the saw for its first cut, it slices a path through the plastic louvers on the sliding tray.

That’s Not Your Father’s Tile Saw Blade

The vacuum not only removes cutting debris, it also cools the specially-designed blade, reducing friction and heat. We put a Milwaukee Thermal imager on the blade while cutting and measured around 109º F after rip-cutting about 8-10 linear feet of tile. That’s around hot shower temperature. Needless to say, the blade stays remarkably cool.

Speaking of the blade, it costs about $99. The proprietary Q-shaped arbor keeps you from mistakenly using a standard diamond blade, which would heat up tremendously and yield less than desirable results. While that may seem like an inconvenience, it actually makes quite a bit of sense given the use of this tool as a system.

Build Quality

With a tile saw, build quality matters. You need to take the tool on and off the job site repeatedly. You also need to be able to use the sliding table without fighting it. A rough table will yield inaccurate cuts and a miserable time cutting tile. It was for this reason that I actually did a double-take when I spied the underside of this dry cut tile saw. There’s more stainless steel in there than in my grandmother’s hips—and that’s saying something. I counted twelve rollers. It’s no wonder the table slides like glass. Compared to the rough slides on the Harbor Freight Chicago Electric tile saw we used to run nearly a decade ago, this felt like silk.

You need to remove the blade guard in order to access the blade and adjust the laser, but this took minimal time. Everything seems well-placed and quite serviceable. It also stayed fairly clean during multiple uses—another benefit of not having to cut with a constant spray of water.

Then there’s the casting of the sliding table. It should last a good long while. Combined with the rollers, the table not only slides smoothly, it slides straight. On the top side, I liked the grip of the rubber pads and the fact that the plastic louvers can be changed should they get ratty over time.

Expand Your Horizons with Accessories

Accessories abound with this saw. You can add the following to bring increased functionality to the iQTS244 tile saw:

iQTS244 Miter Attachment

This attachment adds a miter accessory which gives you up to a 24″ miter cut length capacity. You can miter material up to 3/4-inches in thickness and beveling can occur at either 22.5º or 45º. To make cuts even easier, iQ includes a couple of quick clamps to help you secure material for beveling. The miter attachment costs around $150.

Vacuum Port Hose Kit

The $89 vacuum port hose attachment lets you use the iQ Power Tools dry cut tile saw as a makeshift shop vac. More than that, however, it literally lets the tool clean itself up! We’d call this a “must-have” accessory that extends the usefulness of the saw. It really makes a lot of sense as it easily slides right overtop of the intake port. The iQ Power Tools iQTS244 dry cut tile saw even has a “vacuum-only” switch to power the vac without spinning up the blade.

iQTS244 Extension Table

The iQTS244 Extension Table runs $250 and turns your tile saw into a tile table saw. You just lock the sliding table, remove the fence from the extension table, and place it over the top. Now, you’ve got a durable PVC surface that lets you cut large format ceramic tile up to 4″ or more. We used it to make “rip” cuts on 36″ faux wood tile used in a hallway and bedrooms.

It’s Wheelie Convenient

The iQTS244 Dry Cut Tile Saw comes with wheels on the back and an integrated handle that pulls out easily for transport. More than that, the X-stand folds flat and goes on and off easily. iQ Power Tools made sure that the process of removing and adding the stand was as straightforward as using the saw. You can pop the stand on or off in seconds, and there are no tools needed. It also doesn’t take up tons of room like a Gravity Rise-style stand. Having lugged my share of tile saws around, including the capable but monstrous Bosch TC10 tile saw, this came as a relief.

Using the iQTS244 Dry Cut Tile Saw

Seeing the iQ Power Tools Dry Cut Tile Saw in Las Vegas at the 2016 World of Concrete sold us on having to review it. Getting it into the PTR shop, however, turned our hopes into a reality. It really is that simple to set up and use. It really does cut both porcelain and ceramic easily, and I cut material from both Italy and China. Cross cuts and ripping were equally successful. This saw does great on floor tile, and smaller bathroom tile would cut equally well.

Ripping

During longer rip cuts I did experience a bit more edge chipping on the left side of the blade during cuts. This didn’t seem to matter if I cut quickly or slowly. The right side of the blade stayed nice and clean, however. This might result from the angle of pressure placed forward and right in order to keep the tile riding snug against the fence. Still, it will be more of an issue on a darker tile. I experienced nearly identical chipping on both cross-cuts and rip cuts using the Ridgid wet tile saw. Different saw. Different blade. Similar results.

Since the iQ Power Tools dry cut tile saw doesn’t come with a glass cutting blade, I didn’t attempt to cut any glass tile. That requires a very specific blade that has a uniform coating of diamond. You also need to dress the blade more frequently when cutting glass tile. For now, we’ll stick to manual cutting for glass. Also, since the maximum cut height states 1-inch, we didn’t go for any brick. The iQ Power Tools iQMS362 Dust Control Masonry Saw will handle that when it comes out. Right now, they also sell the iQ360XR Dust Control Table Saw and a Portable Dust Collection System for larger brick and block cutting.

Keep it Clean

The vacuum system works as advertised, and we experienced very little dust or debris on the job site. Clean-up is ridiculously simple, and the entire system makes you wonder why all porcelain tile saws aren’t dry cut. Once we got done for the day, we gave the black handle on the filter cover a few spins and emptied the collection tray. My cleanup went from 30+ minutes down to 5.

Conclusion

There’s a bit of sticker shock with a $1,899 price tag that includes the stand, but we think it will be well worth it. This dry cut tile saw has the potential to absolutely change the game for professional users. Use it, and you may feel a little upset that you’re just now hearing about it.

iQ Power Tools Dry Cut Tile Saw Key Features

- Model number: iQTS244

- Three-stage filtration system

- Vacuum-cooled blade

- Dust tray

- Wheeled stand for transport

- 100% compliant with OSHA respirable silica dust regulations

iQ Power Tools Dry Cut Tile Saw Specifications

- Blade size: 10 in.

- Rip cuts: 24 in.

- Diagonal cuts: 18 in.

- Cutting depth: 1 in.

- Vacuum: 92 CFM

- Dust control: 99.5% (Meets OSHA’s new 2016 silica standard)

- Warranty: 1-year limited

- Price: $1,899

For even more information, check out the iQ Power Tools website.

Watched a lot of reviews. Chip-out, blade type changes required, handling silica dust, tile chips flying all over, and no one explained how you cool a tile while hand trimming and did I mention how slow you have to move to keep the tile cool. Then there is double plus the cost. The concept is great but I will keep my wet saw for now. Sorry

I typically get 70 to 90 cuts on a blade. My rep suggested the Hard Material blade and I got 90 to 100 cuts on that blade. Both scenarios I would run a stone on the blade to start the day. I wish I would have just replaced my Dewalt wet saw with a new one instead of spending the money on this saw. Other issues are you can’t cut angle cuts on bullnose tile, hard to plunger cut, and hard to clean out corners on 90deg cuts such as doorway cuts. Saw blade leaves a significantly worse chatter on… Read more »

I have been using this saw for the past year and have had many problems with the blade dulling (within two months I was told it should last close to a year). I was told by my rep to simply run a cinder block through and it would re-expose the diamonds. This was not helpful advice as I’ve tried that and it continued to spark and not cut nicely. I love the concept and the saw when it works (natural tile it usually works fine for) however I’m frustrated that I’ve had to begin carrying two saws on my van… Read more »

I do tile for a living and saw this at a trade show. It was bar none one of the most impressive tools I’ve ever seen. I am saving my pennies to buy one asap