What is pressure-treated wood or lumber? Well, the conversation went something like this:

Kenny: “Wow, that’s actually pretty impressive… this DeWalt drill just drilled a 2 9/16-inch hole in pressure-treated wood on high speed with no real trouble at all.”

Me: “Cool…wait…what is pressure treated wood exactly?”

Kenny: “Hey, that’s a great idea for an article!”

So, here we are. You’re reading this because I had to go shooting off at the mouth. You see, this is what happens when I ask questions around here. Kenny knows that other people have the same one—so my teachable moment becomes everyone’s teachable moment.

I kid, though. I was actually curious about this topic, and figure maybe scores of others might wonder the same thing. So, I’ll take one for the team and do a bit of research. If you did the right thing and Googled the same question that I asked, you might be here reading this, rather than writing an article about it. So, hat’s off if that’s you.

Anyway, the million-dollar question remains: What is pressure-treated wood?

No Really, What is Pressure Treated Wood?

Classic pressure treated lumber makes use of CCA—chromated copper arsenate. That’s chemistry-speak for chromium, copper, and…arsenic. Wait…arsenic? Sounds like something you really want to spend time swinging on, huh?

However, in late 2003, the EPA made some changes to keep your kids’ playset and your front porch swing a little less toxic. However, the entire reason we use pressure-treated lumber is to make sure what we build lasts longer. That desire remains unchanged. However, CCA still remains in play for non-residential use.

Using Copper Instead of Arsenic

Enter stage left ACQ (alkaline copper quat) as the most popular alternative. CC (ammoniacal copper citrate), ACC (acid copper chromate), and CA-B (copper azole) are other names that can pop up. It doesn’t take long to see the trend. Arsenic is out, and more copper is the key to pressure-treating lumber. Copper helps prevent breakdown by an assortment of insects and fungi. The downside—copper readily releases into the soil and environment around it.

Is Pressure-Treated Wood Stronger Than Regular Wood?

In a word—no. Pressure-treated wood merely conditions the wood for use in ground-contact situations. It helps it resist rotting from water contact and other environmental materials that cause decay in normal wood. This may seem odd since we often see tool-guys cutting on pressure-treated wood.

The reason often has to do with the fact that the presence of water makes the wood feel denser and heavier. That makes it a tad more difficult to cut at times—at least until it fully dries out. Structurally, however, pressure-treated lumber doesn’t outperform white or yellow pine.

How they Make Pressure-Treated Wood

The process of making pressure-treated wood remains the same. Lumber enters into a chamber or tank which gets filled with the chosen chemical agent. The tank then gets pressurized. This promotes absorption into the wood.

That pressurized stage is where the process “pressure-treated” gets its name. Adding pressure to the mix forces the chemical treatment deeper into the wood than it could go with simple soaking.

Wood can air dry in most cases. A better process involves a kiln to bake it in. When the wood requires the extra step of kiln drying, the price goes up accordingly. We prefer kiln-dried pressure-treated wood in most cases.

How Much Chemical is Actually in Pressure-Treated Wood?

The chemicals used in pressure-treated wood don’t do us any favors if we ingest it. That’s why you don’t want to burn PT or breathe in sawdust when cutting it. You might find it interesting to know that there are between 0.40 and 0.60 pounds of chemical per cubic foot of wood, depending on the application.

That’s not a small amount.

When Must You Use Pressure-Treated Lumber?

Codes vary around the country, but in general, you should use pressure-treated lumber in the following scenarios:

- Ground contact or potential ground contact (fence posts, retaining walls, etc)

- Floor joists and sub-flooring within ~12-18-inches of the ground

- Affixing wood to concrete of any kind (walls, foundations, etc)

- Wherever else your building codes require it!

Can You Paint or Stain Pressure-Treated Wood?

Pressure-treated wood takes stain far better than it takes paint. If you wait for the material to fully dry—and don’t live in Florida during the summer—you may have a fighting chance. You come up against several opposing factors. First, the general wetness of the lumber means it has a lot of movement left in it. Paint tends to crack and peel when the underlying wood shrinks and contracts. Second, the chemicals that work so effectively (or not) against preventing rot in pressure-treated lumber also resist paint until the boards completely dry out.

With that said—paint is cheap. If you want to paint your pressure-treated wood—go for it. Just wait for it to dry and be sure to prime it. Also—don’t be surprised if you need to go back after a few years and give it a fresh coating of paint. We do, however, prefer staining PT to painting it when possible. Just be sure to seal it every year if you want it to maintain the look over time.

Wrapping It Up

So there you have it. The next time someone asks “what is pressure-treated wood?” you’ll be the smartest guy in the room. And then your friends, impressed by the depth of your knowledge, will have no choice but to buy you a drink out of sheer awe.

Or not…

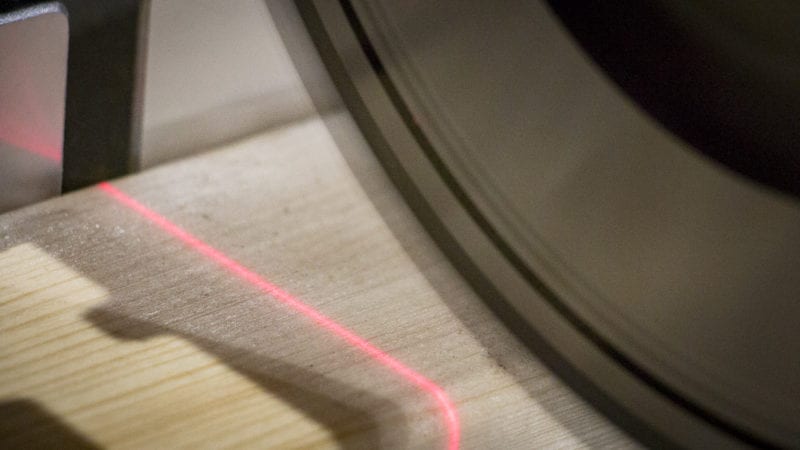

Like the looks of the tool in this article? It’s the Makita XSL06 10-inch miter saw and we love it!

What is the difference between the PT wood you see in the eastern US and the western US? In the east, it’s generally looks like normal wood but with a greenish hue. In the west, it had small indentations all over and is a brownish color.

Still can’t beat the old creosote treated wood. Just renovated a building that had been built on creosote 4×6 beams. The building had settled and the beams have been under ground for nearly 60 years. They had zero rot anywhere. And creosote is probably less cancerous than whatever new Chemical they’re treating it with.

Another question, what are your steps after breathing in the saw dust, I was using my multi-tool for about 20 minutes today after scribing some fence boards and cut the strip.

Didn’t wear a mask but washed my hands. is 20-30minutes enough to cause problems. I’m a non smoker so I’m just wondering. Do I need to see a doctor?