3D printing may be the sexiest technology when it comes to producing prototype and custom parts, but CNC machines have been in the business decades longer. With types ranging from routing and milling to grinding and lathes, CNC machines start around a few hundred dollars and can move way beyond the $100,000 mark. The APSX Spyder CNC Machine is a milling style that currently retails for $3500. Whether or not it’s a good investment for your shop or business boils down to whether it can do what you need it to.

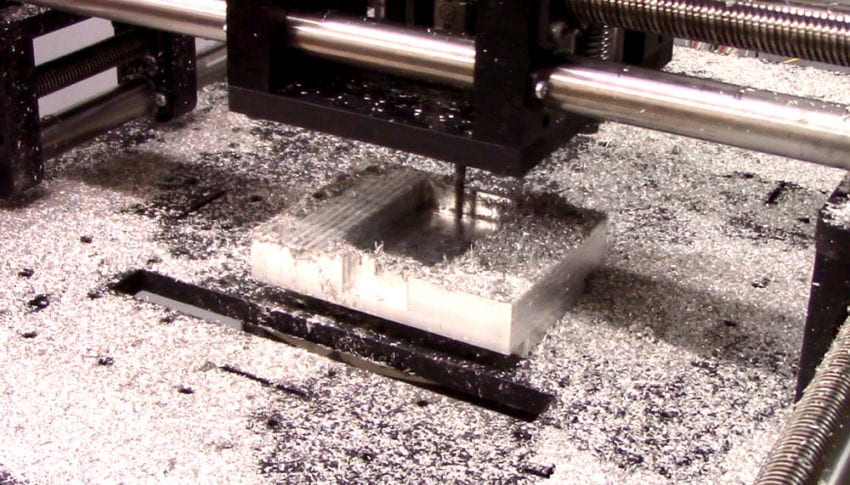

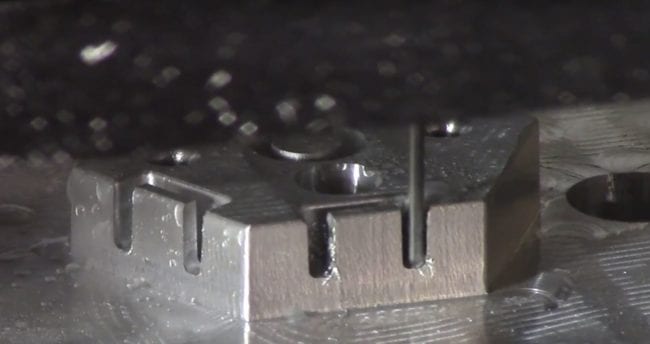

As a milling machine, the APSX Spyder does the majority of its work in metal. It features an auto-misting, water-cooled, 800-watt spindle with a range of 2,000 to 20,000 RPM. While running at low RPM’s, it pumps up the torque to cut in those tougher materials. In the event that spindle coolant runs low (you can adjust the amount in the software), the machine will stop before overheating occurs to the machine, spindle, or bit and remember its XYZ coordinates so you can get it back to work without stopping to home in again.

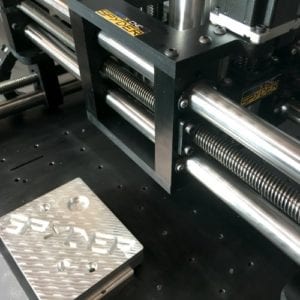

The overall footprint of the CNC Machine is 30″ x 23″, which would take up a little less than half of the desk that I’m currently working on. The actual X/Y travel is 20″ x 13″, covering a pretty reasonable distance for most machine shops. Within that space, you can cover up to 144″ per minute.

Translating the accuracy that a computer can calculate to the motors and the workpiece is directly related to how rigid the machine is. Any wobble during the process can move the bit slightly. APSX promises a rigid build and also offers an optional concrete base to increase that rigidity.

Where it Fits

On the low end of the CNC machine spectrum, you have routers for woodworking products. The APSX Spyder was specifically designed to cover wood and plastic projects but move into the metal milling space. That capability comes at a higher price.

As a completely integrated system, the APSX Spyder comes with everything you need to get started and doesn’t require a separate installation. The computer, keyboard, pendant, and monitor are all part of the package, including a 1-year subscription to Autodesk Fusion 360. It runs on a preconfigured LinuxCNC software package.

A Quick Note About APSX

APSX was conceived in 2002 as the brainchild of two engineers in Xavier University’s MBA program – Rick Cevik and Kubi Kara. Based near Cincinnati, OH, their business model focuses on designing portable smart machines that provide businesses the ability to move from concept to finished product in one day.

This level of prototyping is often only accessible to major manufacturers. But with smaller, simpler, and less expensive machines that still offer intelligence and precision, even small manufacturers and machine shops can bring their products to life quickly. In fact, ASPX claims to offer their tools at 1/3 the price of their closest competitors. Not bad for a couple of really smart guys operating right here in the US.

APSX Spyder CNC Machine Key Features

- Auto-mist & water cooled spindle to keep the temperature down

- High Torque at low RPMs

- Overload protection

- Rigidly built dual shaft/motor to increase precision

- Optional concrete base accessories for greater rigidity

- Complete integrated system, no installation required

- Includes a 1-year commercial subscription to Autodesk Fusion 360

APSX Spyder CNC Machine Specifications

- Model: APSX Spyder CNC

- Motor: Dual on each axis

- RPM Water-Cooled 800W Spindle: 2,000 – 20,000 RPM

- IPM (inch per minute): Up to 144 IPM

- X, Y Travel: 20″ x 12″

- Footprint: 30″ by 23″

- Standard outlet: 120V

- Software: Configured LinuxCNC

- Construction: Steel shaft, hard anodized aluminum

- Overload Protection with Auto-Stop: Yes

- Auto homing: Yes

- Closed loop coolant: Yes

- Includes: Monitor, keyboard and pendant, 1/4″ and 1/8″ endmills

- Price: $3,500 through September 1, 2018

Check out more details about the APSX Spyder CNC Machine here.