The first time I heard of Triton power tools was when I came across the Torque Work Centre. In the product details it mentions that there’s an accessory that attaches Triton routers to the Work Centre. I remember thinking, “What’s a Triton router?” In doing a quick Internet search to find that not only were the routers on the expensive side, there didn’t seem to be much information about them in the US (the company is based in Australia). However, in recent years Triton has been gaining quite a bit of steam here via their affiliation with Kreg. I believe the relationship has changed at this point, but the details are murky. Having no personal experience with the brand, but reading about some of the unique features on the Triton TRA001 router, I was pretty excited to hear that Triton sent one over to get our professional thoughts.

Initial Thoughts

I currently have five different routers at my shop which I use on a regular basis, so it was easy for me to pull the Triton TRA001 out of the box and make an instant comparative analysis. First impression: heavy, well built, and feature-rich. The most prominent feature is the rack-&-pinion plunge dial with micro adjustment, but one of the coolest features is the automatic spindle lock at full plunge for single wrench collet removal. The right handle has a button that switches the router from traditional free-plunge to rack-&-pinion dial adjustment, giving you a more controlled plunge into your work piece. After switching back and forth a few times and getting a feel for the system, I found the operation to be very smooth. When you plunge the router to full depth, the shaft lock engages and locks out the power switch (preventing accidental starting), allowing for single-handed bit change – very nice.

I currently have five different routers at my shop which I use on a regular basis, so it was easy for me to pull the Triton TRA001 out of the box and make an instant comparative analysis. First impression: heavy, well built, and feature-rich. The most prominent feature is the rack-&-pinion plunge dial with micro adjustment, but one of the coolest features is the automatic spindle lock at full plunge for single wrench collet removal. The right handle has a button that switches the router from traditional free-plunge to rack-&-pinion dial adjustment, giving you a more controlled plunge into your work piece. After switching back and forth a few times and getting a feel for the system, I found the operation to be very smooth. When you plunge the router to full depth, the shaft lock engages and locks out the power switch (preventing accidental starting), allowing for single-handed bit change – very nice.

There are a few more details worth noting right out of the box: the plunge stop system is very easy to use and gives you three stopping points, two with measurements. The dust shield system looks very elaborate – I can’t seem to get any of my dust extractor fittings to work in the threaded port of the Triton TRA001, so we’ll go without an extractor for now and see how the shields work on their own. The multi-function fence for edge guiding and (small) circle cutting, can be taken on and off very quickly without any additional tools.

There are a few more details worth noting right out of the box: the plunge stop system is very easy to use and gives you three stopping points, two with measurements. The dust shield system looks very elaborate – I can’t seem to get any of my dust extractor fittings to work in the threaded port of the Triton TRA001, so we’ll go without an extractor for now and see how the shields work on their own. The multi-function fence for edge guiding and (small) circle cutting, can be taken on and off very quickly without any additional tools.

Router… I Barely Know Her

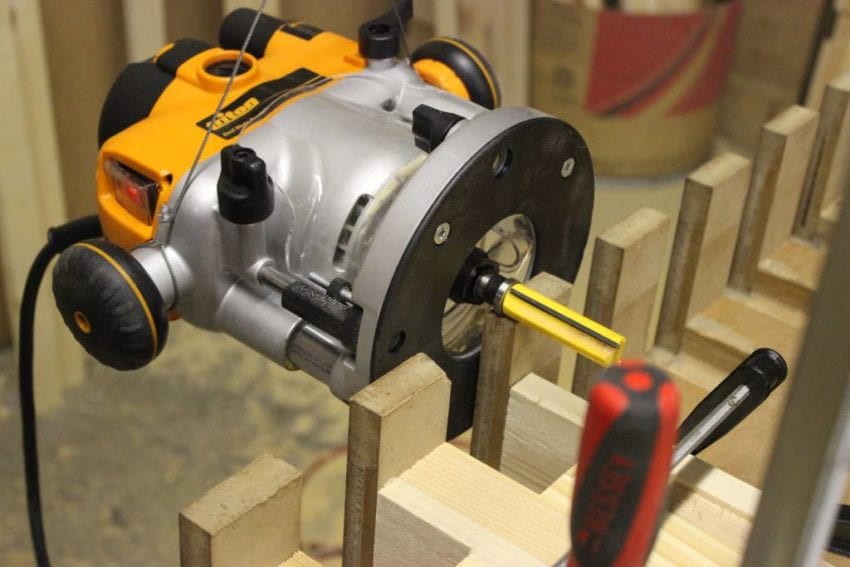

As mentioned above, I have a collection of routers at Seventeen20 (my shop), each one set up for different purposes, based on its individual strengths. The first place I tried out the Triton was in my horizontal template jig for 2-1/4″ deep box joints. I currently suspend my Bosch 1619EVS router from a tool balancer to bear the entire weight of the router. The balancer allows me to focus my energy on keeping the router flat against the template guide instead of on holding 13.2 lbs out in front of myself for a couple hours straight. Although the Triton TRA001 had plenty of power for this deep cut (and actually felt more powerful than my Bosch 3-1/4 HP), the round handles on the Triton didn’t give me quite as much control as the Bosch’s.

As mentioned above, I have a collection of routers at Seventeen20 (my shop), each one set up for different purposes, based on its individual strengths. The first place I tried out the Triton was in my horizontal template jig for 2-1/4″ deep box joints. I currently suspend my Bosch 1619EVS router from a tool balancer to bear the entire weight of the router. The balancer allows me to focus my energy on keeping the router flat against the template guide instead of on holding 13.2 lbs out in front of myself for a couple hours straight. Although the Triton TRA001 had plenty of power for this deep cut (and actually felt more powerful than my Bosch 3-1/4 HP), the round handles on the Triton didn’t give me quite as much control as the Bosch’s.

I decided to leave the Bosch in its current box joint station and float the Triton TRA001 around for a week. I found myself gravitating towards the Triton for larger/deeper plunge recesses into the bottoms and sides of tabletops for steel legs and braces. The Triton TRA001 router’s rack-&-pinion plunge and plunge stop systems definitely shine here. I was able to repetitively plunge to consistent depths with much more control than a free-plunge router. This plunge system is by far the best feature of the Triton router.

There are two drawbacks that stood out to me during “general” routing use, and I’ll admit that the first one may be personal preference because I’ve not seen anyone else mention this about Triton routers—the handles felt too high to me. I constantly found myself reaching for the base with my left hand, just to have some of my forearm on the table for control. The handle position may be tied to the rack-&-pinion plunge system (in which case I’d still choose it for the plunge system, over having lower handles), but it might be worth the effort to offer a removable handle that threads into the base for this type of routing. The second drawback is how quickly the dust buildup inside the shield prevents you from seeing your work piece. This may very well change once I figure out the correct dust collection hose to use. It does, however, seem like a pretty reasonable request to include a dust port attachment that properly threads into the shield system, which would totally eliminate this issue. The internet is littered with users asking about an hose adapter as well. I ended up pulling off the shields for now.

There are two drawbacks that stood out to me during “general” routing use, and I’ll admit that the first one may be personal preference because I’ve not seen anyone else mention this about Triton routers—the handles felt too high to me. I constantly found myself reaching for the base with my left hand, just to have some of my forearm on the table for control. The handle position may be tied to the rack-&-pinion plunge system (in which case I’d still choose it for the plunge system, over having lower handles), but it might be worth the effort to offer a removable handle that threads into the base for this type of routing. The second drawback is how quickly the dust buildup inside the shield prevents you from seeing your work piece. This may very well change once I figure out the correct dust collection hose to use. It does, however, seem like a pretty reasonable request to include a dust port attachment that properly threads into the shield system, which would totally eliminate this issue. The internet is littered with users asking about an hose adapter as well. I ended up pulling off the shields for now.

I Don’t Always Use a Router Table, But When I do, I Prefer Dos Equis… I Mean, Triton.

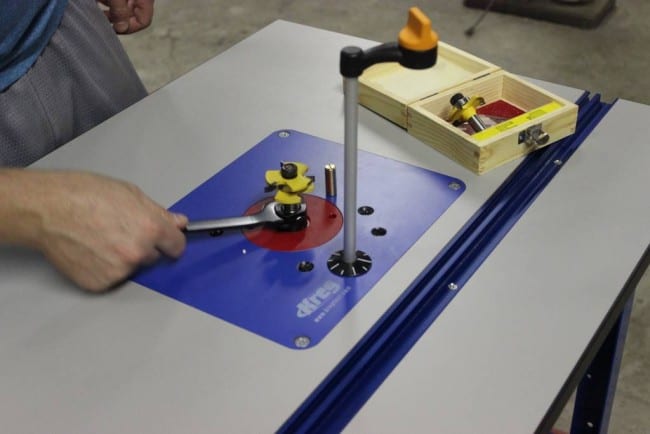

The final position the Triton TRA001 tried out for was the router table. I don’t use my Kreg router table on a daily basis, but it does get a fair amount of use overall and it is currently underpowered with a 2HP router. Aside from the beastly 3-1/4 HP motor, the Triton has three specific features that really stand out in table use: the completely removable spring, the smoothly operating height adjustment, and the automatic spindle lock for single-handed bit changes. My Bosch router has a spring lock for use under the table, but it becomes tricky to engage/disengage when dust builds up under the plate. The Triton spring comes all the way out with one screw. You do have to store the spring, but it feels like a better solution compared to other routers. The height adjustment knob is very smooth and works really well, and when you crank the spindle all the way up, you hit the TRA001’s best “table feature” – the spindle locks by itself. With the collet completely above the table surface, and the spindle locked, changing out bits is very simple. You don’t have to fiddle with holding the spindle lock or using a wrench under the table.

I think I’ve found the Triton TRA001’s new home. The only thing I struggled with by leaving it in the table was losing my overall favorite feature: the rack & pinion plunge. Solution? Pick up one of the Triton MOF001 2-¼HP routers. The design and features are identical to its big brother, but at 25% lighter, it isn’t quite as top heavy. Although the handles are still higher than my preference, the Triton MOF001 feels more stable than the TRA001. The dust shields also seem to function better in the smaller MOF001, especially when routing harder woods. MDF dust still obscures view of the work piece pretty quickly though. Now I have a beast in the table with great features and a more manageable, decently powered, rack & pinion plunge router for free routing and guide use.

Final Thoughts

I’ve long considered my Bosch 1619EVS to be my favorite 3-1/4 HP router, but priced just under the Bosch online, the Triton TRA001 is a serious contender. Where Bosch wins on ergonomics and well-controlled power, Triton takes the lead with innovative features and raw power. If you do much horizontal routing and/or precise template routing, because of the handle design and finely-tuned power, I’d probably recommend the Bosch. However, if you’re a single router shop and do a lot of plunging and table work, the Triton should be a top choice. For a multi-router shop, the Triton is a fantastic choice for the table.

Triton TRA001 Router Specifications

- Depth Adjustment: Micro Winder

- Electronic Speed Maintenance: Yes

- Maximum No Load Speed: 21,000 RPM

- Speed Under Load: 8,000 – 21,000 RPM

- Motor: 15 amp, 3-1/4 HP

- Weight: 13.2 Pounds

- Safety Power Switch: Yes

- Price: $281.55 (Amazon)

- Warranty: 3 Years

Triton MOF001 Router Specifications

- Depth Adjustment: Micro Winder

- Electronic Speed Maintenance: Yes

- Maximum No Load Speed: 21,000 RPM

- Speed Under Load: 8,000 – 21,000 RPM

- Motor: 13 amp, 2-1/4 HP

- Weight: 10.4 Pounds

- Safety Power Switch: Yes

- Price $229.90 (Online)

- Warranty: 3 Years

I’ve had my Triton for a number of years now and prefer it to my Porter Cable 690.