Rockwell may not be a name that is on the tip of your tongue when you think of tools – but if they continue down the path they are currently on – they soon will be. This fairly new company is making some very impressive tools right now that span the industry, from saws to drill guns to sanders. Now, they’ve added a new tool to their arsenal, the Rockwell RK5102K SoniCrafter – an oscillating multi-tool that makes short work of jobs once thought impossible. Plunge cutting into wood? Flush-cutting PVC or copper piping? Not a problem for this handy tool that oscillates at speeds up to 20,000 OPM. To see how it stacked up against the competition, check out our oscillating multi-tool shootout or see our shootout of who makes the best cordless oscillating multi-tools.

With no less than 5 oscillating tools on the market today, the Rockwell RK5102K SoniCrafter has its work cut out for it. Interestingly enough, Rockwell decided to take on the competition by building a rather rugged and durable tool that would work well on any jobsite. The SoniCrafter doesn’t feel like you have to be careful with it. Rather, it’s the kind of tool you can simply toss in the bag and bring with you on any job, knowing it will stand up to the dust, debris and general abuse that comes with commercial and residential remodeling work.

Rockwell RK5102K SoniCrafter Build Quality

Describing this tool is best done by explaining that the Rockwell built an oscillating tool capable of being precisely controlled with two hands. We found that you could easily rotate the tool to nearly any position and still have your hands on the rubber overmold, making it extremely easy to manipulate during use. The rubber covering also keeps any heat that is generated by the tool away from your hands, allowing you to work longer and more accurately. The tool is lightweight, though certainly not the lightest in its class. Still, for a 2.3 amp motor, we found the SoniCrafter to be very workable and easily positioned, even with one hand.

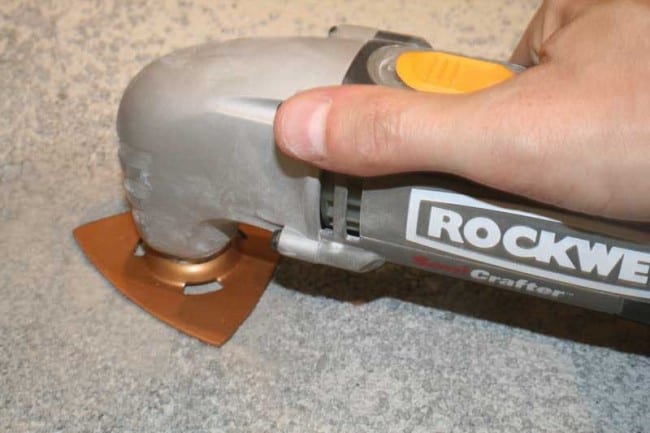

The on/off control is handled by an orange sliding switch which is activated by a casual thumb movement. It’s a good design as it was firm enough to not accidentally activate on its own, yet easy enough that you weren’t struggling to turn on the tool when using it in one hand. The rear of the tool is where you’ll find the adequate 10 foot power corder and 6-speed control dial for adjusting the oscillation speed. While there are six positions, the dial actually ratchets into 11 discrete speeds. While we don’t really expect you’ll need that level of control, it’s there for your experimentation.

Since we found 11 different positions, the tool can be dialed in within increments of roughly 800 OPM (oscillations per minute) steps. It would take a true craftsman to find the usefulness in that level of oscillation speed control, but we know you’re out there and we’re sure it will be appreciated.

Unlike another oscillating tool which we also recently tested, the Rockwell opts for a tool bag and a separate plastic hard case for its accessories. Since the tool is one that will likely “grow” over time with more accessories, we felt this was a good call. For some tools we appreciate well-designed overmold cases, but in the case of an oscillation tool, a bag potentially works better – at least with a more rugged model like the Rockwell. Inside the bag there are separate pockets for storage and a hook & loop strap for securing the tool to the bottom of the bag. Where the SoniCrafter really scored, however, was with the inclusion of a separate case for storing all of its accessories. It’s a basic box with only a plastic clasp, but it kept all of the accessories from floating around the bottom of the bag and gathered them in one place for easy selection and use.

When you purchase the 72 piece version of the SoniCrafter you’ll get a dust extraction kit. This is simply a plastic system that is flat on one end and allows a vacuum system to pull dust from the accessory flange underneath the bottom of the tool and out the back to the collection area. It’s a compact system that gives you the ability to continue gripping the tool naturally and should work well for most fine work. Where there may be potential issues is with rougher woodworking and cutting jobs where the particles are potentially larger. The plastic extraction tube gets very narrow towards the front of the tool, giving larger particles plenty of opportunity to get lodged in place.

Near the exhaust port resides a handy, but troublesome hex wrench holder that is attached to the strain relief for the power cord. It’s handy in that it provides easy access to the wrench, but troublesome in that the wrench will fall out whenever the tool is used upside down vertically, such as when cutting downward on baseboard with an end cut blade. Be prepared to just toss the wrench into the bag.

Changing Accessories

Rockwell’s SoniCrafter has a very straightforward accessory change system. It utilizes a bolt and flange which must be completely removed in order to swap out accessories. Each accessory has a dodecagon-shaped hole that fits over a shallow hex head on the tool. Once positioned, you simply replace the flange and secure the bolt all the way into the tool. In a world of quick-change bits and hook & loop sandpaper, we felt that this was one area that could use some improvement. For one, anything that oscillates at up to 20,000 OPM is going to cause serious stress on a threaded bolt. As a result, we would have loved to see a tool-less accessory change system (such as the one used in the latest Fein multi-tool). The current system certainly works well and it doesn’t take terribly long to unscrew the bolt all the way and insert another blade or sanding attachment. Rockwell even supplies an extra bolt to replace the current one if it is damaged or misplaced.

Accessories

The 72 pc SoniCrafter kit comes with a slew of accessories – far more than many other oscillating tools we’ve seen hit the market of late:

- 30 finger sanding sheets (varied)

- 3-1/8″ semicircle saw blade (RW9120)

- Rigid scraper blade (RW9113)

- 1-3/8″ metal/wood end cut blade (RW9122)

- 2-1/2″ carbide grit segment saw blade (RW9126)

- Sanding pad (RW9139)

- 30 sanding sheets (varied)

- 2 felt polishing pads (RW9146)

- Finger sanding pad (RW9147)

- Vacuum dust extraction adapter (RW9156)

- Triangular carbide grit rasp (RW9116)

Believe it or not, all these accessories fit into the supplied plastic case – but don’t expect to squeeze in even one more – for that you’ll need to start packing in the internal pockets of the tool bag. We added up the accessories included with the 72-piece kit and came up with a total of roughly $225. That’s almost $50 more than the price of a new kit, so it pays to spend a little more up front and get the version of this tool that is packed with the full array of accessories. OK, so the blades, scrapers and sanding pads aren’t exactly cheap when purchased individually, they are a veritable steal when compared to some of the more established competition’s prices.

I really liked, in particular, the sanding pad accessories and Rockwell’s implementation of the hook & loop system. It was extremely strong, allowing absolutely no drift on the pad and yielding a very tight connection between the pad and the paper. The paper was also slightly oversized to the pad, meaning that you’ll damage the pad less than if it were cut exact and the pad was allowed to constantly come into contact with your sanding area. My other favorite was the stainless steel rigid scraper which was deft enough to be used on even smaller grout and scraping projects, but large enough to make itself practical when, for example, lifting up larger swaths of glue-down carpet.

In addition to what comes with the kit, Rockwell also has available a carbide rasp finger blade which can accomplish the same goals as the included triangular rasp, but in tighter spaces. There are both narrow and wide carbide grit semicircle saw blades, and diamond-coated saw blades for scoring and cutting into plaster, porous concrete and masonry. We don’t recommend these for cutting large areas of tile, but they are available for small applications. You can buy a cleaning block for the carbide blades and there are additional sanding pads and tools available for flexible applications. As for sawing, Rockwell provides purchase options for multi-packs of 3 and more specific accessories for wood and metal-only use.

Testing and Use

We used the Rockwell SoniCrafter in a variety of settings. Before we got crazy with the tool and subjected it to our torture tests, we slapped on the rigid scraper blade and went to town on some old caulk that needed to be taken on a bathroom tub. The SoniCrafter made short work of the job, allowing us to easily pull up the caulk as the scraper loosened it up in just one pass of the tool. Never before was I so amazed that a tool actually performed as advertised. We found the easiest way to get all of the caulk out was to slide the tool diagonally across the tile in any areas where the caulk was extended vertically. Once we ensured there was no remaining caulk on the tile, we simply drove the tool along the edge of the tub at a slight angle and watched it pry up the caulk in a largely singular long strip.

The Oscillating Motion

I just like to demonstrate the actual oscillating motion of the multi-tools during a review for those who don’t quite understand how these tools function. As you can see below, there is a 3.2 degree movement (in total) for the tool’s accessories. That means that when you insert a sanding pad the entire sanding pad is oscillating in a circular back-and-forth motion a maximum of 3.2 degrees. As you can see below you get a lot of sanding power and motion without the reactive inertia generated by a rotating tool. This means the SoniCrafter can do a lot of functions with very little vibration coming back onto your hands.

After our caulk test, we took the sanding pad and slapped on some 220 grit paper to do some finish work on a custom wood surround we were installing into a bathroom to cover the bottom of a whirlpool tub. The sanding area was plagued by small, narrow areas that needed to be sanded, but which wouldn’t do as well with traditional, more bulky sanding tools. The Rockwell did a tremendous job of allowing us to, with only one hand, maneuver the tool into tight spaces and get the job done. Working with the SoniCrafter afforded us a level of freedom not found in typical orbital sanders.

In preparation for placing a mat and second layer of concrete into a shower floor, we decided to give the carbide grit triangular rasp a trial by fire. Smoothing out some of the concrete texture left over from an unorthodox method of laying the first layer of concrete (shaping the concrete then misting it to saturation with a hose) we were able to get rid of the larger texture mismatches and allow the mat a smoother surface on which to get sandwiched into place.

On our test bench, we plunge cut the 1-3/8″ universal end cut blade into a piece of pressure-treated lumber. It took a while for the blade to make it into the wood to its maximum depth of 1-5/8″, but that was likely due to the fact that this blade was more designed for metal work than wood. Our recommendation is to grab an RW9121 end cut blade ($20) that will do far better on wood applications. This one got the job done, but we were able to see it bind up due to the teeth simply not being able to “cut it” (pun intended) on our sample hard wood piece. For a piece of simple pine or on baseboard material it will likely do just fine. In fact, we just so happened to have a project that required a couple notches be cut into a piece of particle board in order to properly mount some file folder hangers in a drawer. Taking the Rockwell SoniCrafter we were able to plunge cut our notches and complete the task in no time flat. Cutting two blade widths right next to each other would be impossible for a rotary tool, but the oscillating motion of this device made it easy to simply plunge cut and then start another cut immediately adjacent to our starting position.

As the blade we grabbed was not optimized for wood, we quickly switched over the metal and found that the accessory made quick work of cutting off a piece of copper piping. Realize that carefully lining up this tool is important before starting your cut, but it’s not difficult. We were able to easily line up the SoniCrafter with one hand to begin our cut. It was actually much faster and just as accurate as using a manual pipe cutting tool – with the additional benefit of allow us to cut it flush to the wall. Try that with another tool!

When using the tool with drywall we found that it worked best when the area to be cut was first scored with the tool. After scoring the tool sliced through the drywall like butter and making holes for electrical boxes and switches was a piece of cake. Well-rounded doesn’t begin to cover this tool – it’s one of the most versatile pieces of equipment you’re likely to ever buy.

Conclusion

The Rockwell SoniCrafter doesn’t just feel like a solid tool, it comes through with the power and performance to back it up. The storage bag and accessories case make it an easy tool to bring to the jobsite and its rugged build quality means you don’t have to treat it with kid gloves in order to use it on your construction and remodeling jobs. The Rockwell implementation of the multi-tool leans more towards the builder and less towards the hobbyist. That’s not to say that the artist and hobbyist can’t use it, but there are lighter, more maneuverable tools on the market for that sort of work. For the serious builder or home remodeler, the Rockwell SoniCrafter is quite possibly the best oscillating tool we’ve seen apart from the original Fein MultiMaster.