Fiber cement has been around for over a hundred years but it really came into widespread use as a substitute for asbestos cement in the 1980s. Fiber cement’s cellulose fibers replaced asbestos fibers as the reinforcing members in building materials, eliminating the risk of diseases resulting from asbestos inhalation. But that doesn’t mean that all danger is gone. When fiber cement is cut, it creates respirable crystalline silica dust, which wreaks havoc on our tools and lungs. In fact, just last year OSHA reduced the exposure limit to crystalline silica dust in an attempt to stem the danger of silicosis. The good news is that a little prevention goes a long way, as does some help from the cleverly designed Skilsaw Fiber Cement Circular Saw.

First Impressions

The Skilsaw Fiber Cement Circular Saw might look like any other circular saw you’ve ever seen except for a blade guard that tapers into an 8-foot hose. Of course, that gets connected to your dust extractor with the included 1-1/2- or 2-1/2-inch adapters. In this way, most dangerous particles should be captured by the suction and safely bagged instead of collecting on the saw or worse still, inhaled by the user!

For the particles that aren’t captured, there are sealed motor bearings and a dust resistant switch. What’s not sealed is your respiratory system, so be sure you know this saw is no substitute for a respirator.

A no-mar nylon sleeve covers the hose and 10-foot power cord to prevent snagging and cutting through your own cord.

The 15-amp motor is on the high end of the circular saw power spectrum and it’s needed since what it cuts is tough stuff. It’s a sidewinder model with Skilsaw’s 67 series motor rather than their 77 series worm drive. Expect some torque to be given up for higher speed and lower weight in a sidewinder if you’re comparing the two styles.

Skilsaw balances out the weight with some magnesium components, resulting in a saw that’s burly without tipping the scales too terribly at 9 pounds. Diablo’s HardieBlade makes up the business end of the saw with its unusual 4-tooth design. We have some fiber cement siding to cut, so let’s get to it.

We Also Reviewed Diablo’s 10-Inch Hardie Blade

The Not-So-Healthy High Fiber Diet

We plugged the saw’s cord into power and the hose into the vacuum. The saw lacks a safety switch and, quite frankly, that’s usually preferred by Pros because it eliminates an annoying step. Others will surely knock the lack of this safety feature as being a serious oversight.

When I pulled the trigger, I immediately noticed the saw’s outstanding stability. There was no blade wobble or rocking, which helps make straight, clean cuts. Since fiber cement doesn’t have a grain like wood does, you’ll notice that both rip and crosscuts feel the same: there’s no path of least resistance along the grain like wood.

If you’ve ever cut fiber cement products without a dust extractor, you’ll know the dust cloud created is huge. Skilsaw’s dust mitigation is really impressive as it only allows a couple of puffs of dust into the air. It’s good for the guy cutting and everyone else on the jobsite since the dust cloud can hang over the area long enough to inhale an unhealthy amount. Still, September 23rd is the deadline for new OSHA compliance, so be sure you have your PPE in order.

The dust is also hard on saws, so time will tell if the sealed motor bearings and dust resistant switch are helpful. Frankly, there’s no way to truly protect the motor and also have it vent properly, so some buildup inside the tool is inevitable. Those tiny particles will likely build up inside the blade guard so that it doesn’t slide smoothly, too. Of course, that will happen at a much slower rate than a saw without the Skilsaw’s dust extraction.

The effectiveness of the Skilsaw Fiber Cement Circular Saw is a function your vacuum’s power. I used an old 3 horsepower ShopVac that has seen better days. Upgrading to something like the Bosch VAC140A will likely eliminate nearly all of the dust. And let’s be honest, the new OSHA rules will require more effective collection than many Pros currently use, especially on small crews.

Pro Tip:

The saw can remove a lot of the dust from ever entering the air, but it’s still no substitute for a respirator – wear one!

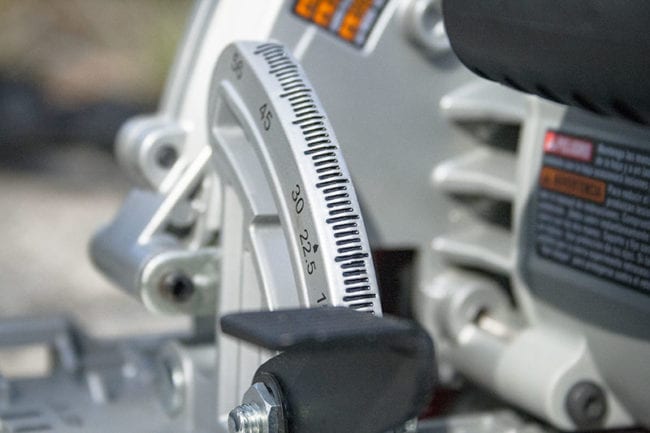

The standard components of the Skilsaw Fiber Cement Circular Saw work just fine. I like the nice, wide shoe. It can bevel up to 56 degrees with stops at 0 and 45 degrees.

The motor is well-powered for the task. Regular readers know that Diablo blades are top performers. Some guys have stopped buying the HardieBlade. Instead, they buy a pack of cheap framing blades and just toss them when the fiber cement turns them into butter knives. You’ll have to decide what’s best for your job, but we find that the life of a Diablo blade typically pays for itself with the number of cheap blades you go through.

I came across a few people who couldn’t make a snug connection between the Skilsaw’s hose and the vacuum adapters. I didn’t experience this but keep an eye on the connection to make sure you’re not trading one dust cloud for another.

The Bottom Line

The Skilsaw Fiber Cement Circular Saw adds a dust collection port and upgrades the durability of their standard sidewinder saw to create a tool specifically designed to cut fiber cement board. That design helps prevent damage that will occur quickly with a standard saw and eliminate much of the airborne silica dust created. The Diablo HardieBlade it’s paired with also helps reduce the overall amount of dust created.

Overall, dust collection is noticeably improved, even using a 3 horsepower ShopVac as a dust extractor and should be very effective with a high-end extractor. It’s not going to be perfect, so a respirator is still in order and you’ll need to check how close to compliance you are with the new OSHA standards set for September 23rd of this year.

Besides the extraction capability, the stand-out feature of this saw is its excellent stability upon startup. Any blade wobble will throw more dust in the air and result in poor quality cuts, so that’s a big deal.

One feature that’s missing is a rafter hook. It’s nothing close to a deal-breaker, but it would be nice to have one.

The upgrades will come at a $70 premium over a the Skilsaw SPT67WM-22 Sidewinder. Even at $169, I can easily recommend this saw to anyone cutting fiber cement material. This is a saw that once you try, you won’t go back to the old way of cutting!

Skilsaw Fiber Cement Circular Saw Manufacturer’s Key Features

- Unique dust collection design channels silica dust away from the tool motor for longer life

- Sealed bearings and a dust resistant switch protect the saw from silica dust for longer life

- No-mar sleeve keeps cord and hose out of your way

- Diablo HardieBlade included for optimal cutting right out of the box

- Lightweight magnesium components for less user fatigue

- Dual-Field Motor ensures best-in-class performance and durability

- Includes Skilsaw SPT67FMD, 4-tooth Diablo HardieBlade for Fiber Cement, 8-foot vacuum hose with nylon sleeve, 1-1/2-inch vacuum hose adapter, 2-1/2-inch vacuum hose adapter and multi-function wrench (stored in foot)

Skilsaw Fiber Cement Circular Saw Specifications

- Model number: Skilsaw SPT67FMD-22

- Blade: 7-1/4-inch

- Arbor: 5/8-inch

- Cord length: 10 feet

- Height: 9 inches

- Weight: 9 pounds

- Power: 15 amps

- No load RPM: 5,300

- Gearing: sidewinder

- Foot material: magnesium

- Gear housing: magnesium

- Motor housing: resin

- Max cut depth at 45°: 1-7/8-inch

- Max cut depth at 90°: 2-7/16-inch

- Bevel: 56°

- Bevel stops: 0°, 45°

- Blade location: right

- Blade included: 4-tooth Diablo Polycrystalline Diamond-tipped

- Warranty: Skilsaw’s 1-year limited Stay True Guarantee

- Price: $189.00

If it meets osha standards.