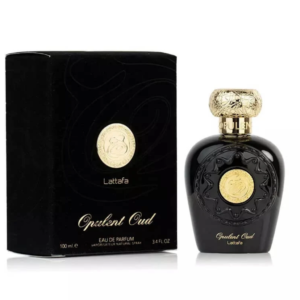

Lattafa Velvet Oud EDP 100mL

You Save: $ 331

Size 100mL

Made in France

Ships within 2 working days

Perfume Velvet Oud Eau de Parfum by Lattafa Perfumes is a velvety perfume with incense, noble Oudh, golden amber and sensual musk.

An elegant, warm, oriental perfume with a linear fragrance line, suitable for any occasion.

Main scents: balsamic, amber, smoke, Oudh, musky

3 in stock

Free Delivery In 3 To 5 Days

Free Delivery In 3 To 5 Days

Reviews

There are no reviews yet.