Picking the Right Blade

When trying to determine who makes the best corded reciprocating saw you need good blades. If you remember back to your days in science class, the goal of any good experiment is to control as many variables as possible. Then, only what you want to test actually varies. We first needed to set up a system that would put each saw through a variety of tests. Those tests reflected what each blade could perform. We knew we needed a blade that would cut through nail-embedded wood. We needed another that could handle steel and PVC. With lots of available options, we settled on the Milwaukee Ax and Torch reciprocating SawZall blades.

Editor’s Note: We got to check out Milwaukee SawZall blade manufacturing in Greenwood. Check out that article for a cool behind-the-scenes look!

Why Milwaukee Sawzall Blades?

There is some confusion out there about recip saw blades. Many folks think that because a tool has a branded name, like the Milwaukee Sawzall, you can only use that blade brand. This isn’t true. Recip saw blades fit in any of the major manufacturer’s saws giving you the option to choose both the saw you think is the best and pair it with the blade that you prefer.

Several thoughts went into deciding on Milwaukee Sawzall blades for our test. Two, in particular, stood out to me. First, Milwaukee is constantly innovating within its company. “Disruptive Innovation” is part of their corporate culture. In fact, t’s nearly impossible to talk to someone at Milwaukee without hearing that term. Second, Milwaukee invented the reciprocating saw. When you’re the one to design anything from the beginning, you are intimately knowledgeable about it. We counted on this combination of innovation and knowledge to produce the best blade for our testing… and we weren’t disappointed.

Editor’s Note: Check out our best SawZall blade article for our top picks.

The Milwaukee Ax Sawzall Blade

As the name would imply, the Ax is designed for wood cutting duties. In our testing, we used nail-embedded wood, which this blade is designed to deal with.

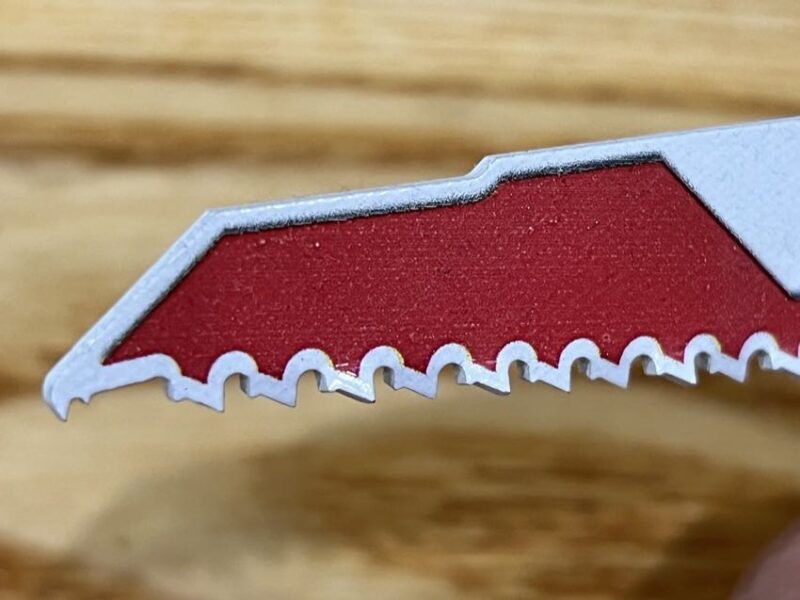

Of the Milwaukee Sawzall blades, the aggressive Ax, with its Fang Tip seems the most aggressive. This tip bites into the wood on contact instead of bouncing up or sliding with the motion and/or vibration of the recip saw. I say “or” vibration because a couple of the saws we tested, including the Milwaukee Sawzall, had very little vibration at all.

A Nail Guard design prevents most nails that you will encounter from slipping between the teeth and causing damage. The blade is thicker to better resist bending and fracturing for greater durability. Also, its 1-inch height helps keep the Milwaukee Sawzall blades more rigid. This makes for straight and accurate cuts. Finishing off the durability features are the Matrix II bi-metal teeth.

The Sawzall Ax Blade is available in either 6-inch, 9-inch, or 12-inch lengths. They feature a 5 TPI design (teeth per inch). They are sold in packs of 5 or in bulk packs of 25 or 100.

The Torch with Double Duty Upgrade

With a name reminiscent of a cutting torch, the Double Duty Torch blades were our metal cutting Sawzall blade of choice. We used the Torch to cut through steel pipes, a U-shaped unistrut piece, and PVC.

The Torch Sawzall Blades have an optimized tooth design that increases the lifespan up to twice the previous generation. Tough Neck ribs strengthen the tang of the blade to improve durability where it is shorter and therefore weaker. The Grid Iron honeycomb pattern increases the rigidity to help keep the blade from buckling.

Double Duty Torch blades are available in lengths of 6″, 9″, or 12″. Tooth options include 10, 14, 18, and 24 TPI. Like the Ax Sawzall blades, these are available in packs of 5 or bulk packages of 25 or 100 blades.

Other Milwaukee SawZall Blades to Consider

- Milwaukee Ax and Wrecker Carbide SawZall Blades

- Milwaukee Torch with Carbide Teeth

- Milwaukee Nitrus Carbide Reciprocating Saw Blades

- Milwaukee Flush Cut Blade and Rough-in SawZall Blade

How Did the Sawzall Blades Perform?

We put each recip saw through 12 inches of nail-embedded wood with the Ax. The Torch was used to cut 4 pieces of PVC pipe followed by that U-shaped unistrut beam. In a separate test, the Torch blade had to make it through 5 steel pipes.

The greatest compliment that we can offer for both the Double Duty Torch and Ax Sawzall Blades is that we didn’t have to think about them during the shootout. We had plenty of spare blades on hand in case they failed during the test for any reason, but that never happened. The blades performed flawlessly, resisting buckling and we experienced no breakage. Even cutting through 5 steel pipes rapidly, there was no noticeable decrease in performance due to dulling or breaking of the teeth.

Considering not only the tasks we required of each blade but also the rapid speed in which we abused them, I came away very impressed. The next time you’re standing in your local Home Depot staring at the multitude of recip saw blades available, don’t hesitate when you see the red packaging of the Milwaukee Sawzall Blades.

My crew wasted many hours trying to cut deck screws to remove decking with 18tpi The Torch. The blade dulled quickly and the box of 10 blades spent with only 10 planks of 20ft decking removed. I bought Lenox gold bimetal 14 tpi and the remaining 5 were out in 30 minutes and the two blades that started were still good. I have no idea why the torch performed so poorly, costing me a lot of time and money.

[…] reading Milwaukee Sawzall Blades: Ax and Torch, originally posted on Pro Tool Reviews. Give us feedback at Facebook | Google+ | […]

saaawzaaaw – trademark

Actually LENOX invented the Bi-Metal recip blade not Milwaukee for plumbers who used their famous hacksaw blades and frames. Milwaukee blades use to snap off a lot in cutting steel piping during repair work. Lenox made bi-metal band saw blades very early about the same time Milwaukee was pioneering the portable electric recip saw. They only made high speed steel (metal only cutting)and carbon steel (wood cutting) blades for their saws. Lenox heard about this frustration by plumbers using Milwaukee blades and LENOX started making shatter-proof cobalt high speed steel teeth with spring steel blade bodies in 1977 to eliminate… Read more »