There are plenty of excellent options for off-the-shelf work boots out there. For some people, the throw-away consumable mentality is wearing thin, though. We had the opportunity to put our feet in a pair of Nicks BuilderPro handmade boots for a review and see for ourselves the difference wearing a boot that thinks long-term can make.

Nicks BuilderPro Handmade Boots: Not Your Ordinary Shopping Experience

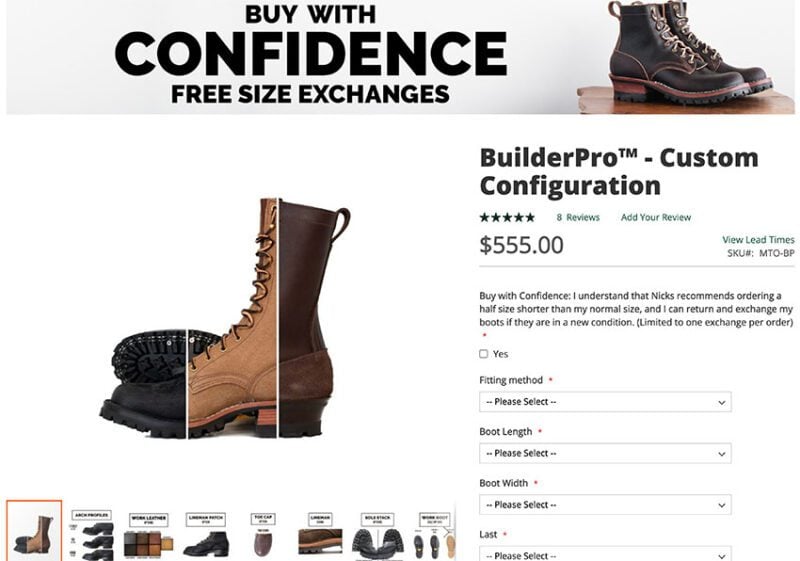

With most work boots, you root through the boxes on the shelf or hope the online retailer has your size in stock. With Nicks, every boot is made by hand once you order it. It’s not quite a completely customizable process, but there are a ton of options.

Because the boots are handmade, there is a lead time consideration. Material availability, amount of labor required, order demand, and other build chain elements have an effect. Give yourself enough time before you need a boot replacement a be patient—the final product is worth it. Here’s what lead times are running at the time we’re writing:

- Standard lead time: 16 – 24 weeks

- Quick ship and best sellers: 8 – 12 weeks

- Size exchanges and warranty boots: 3 – 5 weeks

- In-stock boots: 3 – 5 business days

If you want the most options, go with the BuilderPro Custom Configuration to get exactly what you want. Here are the selections you can make:

- Fitting method

- Boot length (size)

- Width

- Last

- Height

- Upper Leather (color)

- Lower Leather (color)

- Hardware Configuration

- Inside Lineman Patch

- Midsole Thickness

- Toe Structure

- Toe Style

- Lineman Shank

- Sole Stitching Thread

- Heel Stack

- Outsole

- Edge Color

- Heel Profile

Nicks BuilderPro Handmade Boots Design

Fit

I’m a size 12 1/2, which means I usually have to choose between 12 and 13 with most boot brands. However, Nicks has sizes from 3.5 – 14.5 with 1/2 sizes running the full range. You’re not just stuck with medium (D) and wide (EE) widths, either. There are nearly a dozen widths available ranging from AA to FFFF.

In chatting with Lucas Grasberger from Nicks, he told me that he hasn’t been able to find another brand that has more stock size options than they carry.

I was happy to go with a 12 1/2 in medium width with a regular arch and the fit was fantastic. That said, Nicks does recommend ordering a 1/2-size down from your normal boots. If the fit isn’t quite right, you can exchange them as long as they’re in like-new condition.

First Impressions

As you get ready to open that Nicks box for the first time, go ahead and close your eyes and enjoy the smell of that natural leather as you do. There’s nothing like it.

When I slipped my feet in my first thought was “blessed arch support, there you are.” In terms of full-foot support, I can’t remember having anything better on my feet.

The boots come with a leather insole. If you’re on the wrong side of 200 pounds and the wrong side of 40 years of age like I am, you’ll want to add an insole with some extra cushioning. That could be something off the shelf or a custom orthotic; it’s your call.

The leather laces come long. Once you determine how much extra length you want, go ahead and clip the excess with a pair of scissors.

Break-In

To their credit, most modern off-the-shelf boots are capable of working long days out of the box without much break-in period. That’s not the case with Nicks handmade boots, though. With the quality of the materials and construction, plan on spending a couple of weeks breaking them in at the least.

The leather will begin to loosen up as it stretches and the sole will develop the flex it needs to move with your foot. Plus, it will take the shape of your foot better than other boots through the break-in period. Persevere through, though—it’s worth it once they hit your stride.

Wearing Nicks BuilderPro Boots

Once you get through the break-in period, you’re off to the races. Well, off to the jobsite, anyway. There are several things you should be aware of if you’ve never worn boots of this quality before.

The leather is thicker than most. At 7 – 8-ounce, it’s nearly twice the industry standard for uppers. The boot doesn’t have fiberboard, cork, or synthetic fibers. It’s all oak tanned leather from right here in the USA. That all adds durability, but also makes a heavier boot. The boot is also completely rebuildable and resoleable.

The heel and aggressive Vibram V-100 lug sole make the BuilderPro a great choice for jobsites where you’re spending a lot of time on soil. If you’re primarily on concrete, steel, and other hard surfaces, you might want to go with a lower heel or shift to a wedge.

The style of the boot varies with your choices, but in general, it has an overall aggressive, yet professional look. The outsole gives the boot its aggressiveness while the smooth upper can easily pass for a dress boot. If you’re in the upper levels of your construction firm, it looks good in the board room with all the stability and grip you need for the jobsite.

Nicks BuilderPro Handmade Boots Price

The price of your boots depends on your choices. The configuration I went with runs $555.00. Most of the pre-configured best seller versions run $545.

One thing to keep in mind as you’re considering the investment of a handmade boot is that Nicks is a USA-owned company out of Spokane, Washington. Some of their bootmakers have been with them for decades and the company itself has been around for nearly 60 years. More than 98% of the material they use is directly from the United States. Even the leather comes from US-based tanneries.

The Bottom Line

Moving from off-the-shelf boots to quality handmade boots is a big change and there are several things you need to consider. If you’re looking for a relationship with your work boots that’s more than just a short-term fling, we highly recommend taking a look at the Nicks BuilderPro or their other handmade boot options and experiencing them for yourself.

Visit Nicks Handmade Boots website by clicking here.

Properly taken care of, Nicks boots will last a lifetime. Maybe a resoling or two, especially if you use Obenauf’s boot treatment, none better.