We’ve been reviewing cordless finish nailers for many years now. In fact, many products are in their second or even third generation of tools. Still, should you jump in and pick up one of these battery-powered nailers? In an effort to keep you from spending your hard-earned money on something that sounds too good to be true, we created a great guide on pneumatic vs cordless nailers. After all, you don’t want to get burned when it comes to tools so critical to your business.

Pneumatic vs Cordless Nailers: Cost

Cordless nailers may seem to come with a bit of a sticker shock compared to their pneumatic air-powered cousins. A cordless nailer like the Milwaukee M18 FUEL 18ga brad nailer comes in with a bare tool price of around $279. Compare that to products from Makita, Senco, and DeWalt which run between $70 and $99 for a similar pneumatic.

Neither tool can run by itself, however. The cordless model will run $399 with a 3Ah battery and charger. For the pneumatic, you need to toss in a good compressor like the Rolair VT25BIG. Add in a hose and fittings, and your cost of entry is right up there with the cordless nailer.

The other cost consideration is that most Pros don’t live on one nailer alone. Adding a narrow crown stapler and a larger finish nailer, like a 15- or 16-gauge, are par for the course. If you take the Milwaukee M18 FUEL nailers, they will run you around $299 without a battery and charger. Go with the kit and you will pay between $399 and $429.

Realistically, you’re going to want at least one of them to come with a battery if you don’t have other batteries from the same platform already in your arsenal. On the other hand, you can pick up the pneumatics for around half the price or less.

Pneumatic vs Cordless Nailers: Ergonomics

In this debate, the ergonomics are much less about the design of the handle and rubber overmold. The first consideration is weight, which is easily in favor of the pneumatic models. Even when you consider the weight of the hose that is hanging down, there’s a big difference between a finish nailer weighing around 2 pounds and a battery-powered model that can push the 7-pound mark or more.

It doesn’t end with weight, though. With a cordless nailer, you’re not dragging around a hose at all. You’re not tripping over it, it’s not throwing off the balance of the nailer while you work at various heights and angles, and you’re not tethered to a specified length. There’s also no compressor noise in the background. If you’re working in an area where people are present, this is a major bonus.

Pneumatic vs Cordless Nailer Performance

Having tested most of the current batch of battery-powered cordless nailers on the market, they perform very well. Most perform as expected and provide hassle-free nailing. Neither pneumatic nor cordless nailers stay jam-free forever, but proper maintenance keeps them firing effectively.

You will, however, typically notice a significant difference in the firing cycle. Pneumatic nailers fire as soon as you pull the trigger—as you’d expect. Cordless models typically don’t fire nearly as quickly. Part of this has to do with the difference in mechanisms used for these battery-powered nailers. Speaking in general terms, two types of battery nailing technology exist on the market:

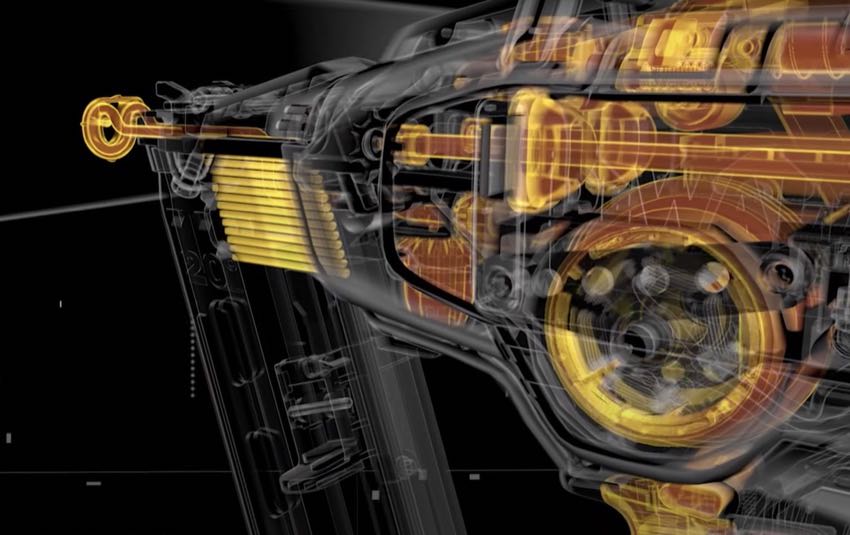

Flywheel-based Cordless Nailers

Cordless nailers that use a flywheel require that flywheel to spin up (get up to speed) before firing a nail. Because of this, the first nail takes a second or so to fire. It can be frustrating and differs significantly from the feel of a pneumatic tool. Porter-Cable, Bostitch, and DeWalt cordless nailers all use flywheel technology.

Nitrogen Cylinder-based Cordless Nailers

The defining characteristic of gas cylinder nailers comes from their use of a captive volume of nitrogen. The tool uses the battery and motor to pressurize this cylinder. Once pressurized, it sits ready to fire instantly—much like a pneumatic nailer. The system works as a closed-loop system.

Because the (often brushless) motor applies force on the upstroke, the driver shoots a nail the instant the trigger is pulled. We prefer these nailers over flywheel models. They also tend to be smaller in size since they use a more compact firing mechanism. Milwaukee, Senco, and Metabo HPT cordless nailers all work using a system like this.

Cordless vs Pneumatic Nailers: Run Time

Considering the run time of both types of nailers almost seems unfair. Pneumatic nailers will run until your power goes out or you have to wait for your air compressor to recycle. The lowest run time cordless nailers will still drive hundreds of nails on one charge with a compact battery. Some nailers are capable of firing more than 1600 shots on a single charge.

Where things get interesting is when the nailer stops. For the cordless model, you swap batteries and put the used one on a charger. Even using compact batteries, it’s unlikely you’ll outwork two batteries being cycled.

For longer and larger jobs, pneumatic nailers still make a lot of sense. It’s rare you have an issue with the power, compressor, or hose. For most work, run-time isn’t the limiting factor. Instead, we turn back once again to weight and overall ergonomics.

Maintenance of Pneumatic vs Cordless Nailers

The pneumatic nailer uses a simpler design than its battery-powered, cordless counterpart. However, there are more pieces tied together in the pneumatic. You have to ensure that your hose isn’t leaking. Couplers and NPT connections need to be well-sealed.

The compressor should have enough gas or you need it to be plugged into a reliable power source. You also have to remember to oil your nailer every day and keep track of your compressor’s oil levels (if needed).

All of those considerations become null and void with cordless nailers. You just need a couple of batteries to get working. You do, however, have a lot more moving parts. You also have electronics and a motor. Far from a simple mechanical air-powered tool, cordless nailers introduce additional complexity to an otherwise simple tool.

When we think about the maintenance of pneumatic vs cordless nailers, the manufacturer’s warranty really comes into play. Since most people lack the training and skills to truly repair a battery-powered nailer, having some warranty recourse sets you up to understand how long you can reasonably expect to use the tool at a minimum.

Pneumatic vs Cordless Nailers: Setup and Take Down

Just for fun, I decided to time how long it took to get my gear from the truck until I fired the first nail. With the pneumatic combo, it takes two trips. The first trip brings the compressor and the second adds the nailer and hose. Of course, you have nails and other materials, but that happens with the cordless nailers as well.

By the time I got the gear, found a plug, connected the hose and nailer, and got the compressor up to operating pressure, I was more than 6 minutes in.

My cordless nailer took just 30 seconds from pulling it off the truck to firing the first nail.

I was just running a test at ground level. When you add in hiking through or around a house to the back yard or going upstairs, the time starts to pile on. As you move through your workday, you’ll find that you also have to continue moving your compressor and hose.

Then, at the end of the day, it’s going to take the same two trips to get your pneumatic gear back to the truck. You’ll just be more tired at that point. With a couple of room changes, going with a cordless nailer system can easily save you 30 minutes. You save even more time the more you move around the jobsite.

The Bottom Line

So should you go cordless or stick to the traditional pneumatic way of doing things?

If you can afford it—both. And that’s not a copout. We have and use both types and so do most of the Pros we work with.

We still recommend pneumatic nailers for larger projects. That includes framing, built-ins, or trimming out an entire house. It makes sense from both a cost and ergonomics standpoint. The pneumatic solution costs less and the tool weighs much less in your hand as you use it for extended periods of time.

You will, however, get to the meat of punch list and project work much more quickly with a battery-powered cordless nailer. Small jobs will simply set up and tear down more quickly with cordless tools.

At the end of the day, both pneumatic nailers and cordless nailers have their place. I’m not ready to say that either one can displace the other completely anytime soon.

What do you think about the pneumatic vs cordless nailers debate? Let us know in the comments below or by shouting out on Facebook, Instagram, and Twitter!

That was a very helpful article and completely helped me decide between an electric and pneumatic nailer (I’m going with electric, because I am a hobbyist, not a professional!).

Very informative article. Myself I will move to battery power. FYI: The title is incorrectly stated, “Pneumatic Vs Cordless Nailers: What’s the Best Choice?”. Recall your grade school grammar lesson about good, better, best. When comparing two items use better, when comparing three or more items use best. Yes, it does make a difference.

Any differences / concerns from a safety standpoint? Is eye protection a must or best practice? Thanks!

What about using a simple hammer ?

takes me 3 seconds to grab it,and 5 sec to finish it.

I don’t know why, but I can’t get a cordless to shoot an 18ga nail through baltic birch plywood. It always leaves the nail with about a 1/4 to 1/2 inch to go. This leads me to wonder, what else can’t I shoot it through? Do I really want to find out the hard way? Until they are more reliable, I won’t risk ruining my workpiece.